When durability and longevity matter for your construction fastening needs, some hardened nail options to consider include concrete nails, stainless steel collated nails and 21 degree framing nails. These fastener types offer benefits like corrosion resistance, higher tensile strength and reduced splitting to withstand demanding fixing applications. Here are details on these durable nail options and factors to keep in mind when using them.

Concrete Nails

Concrete nails feature specially hardened points and shafts designed for fastening into cement and masonry. Made with heat treated carbon steel, concrete nails are significantly harder than standard steel nails to withstand the abrasive nature of concrete. Their nail points feature two chisel edges instead of the usual one to aid penetration into solid surfaces. Common applications of concrete nails for framing include attaching forms to concrete during pouring, fastening fixtures to masonry and anchoring timbers. Length, diameter and head style of concrete nails vary based on the required load bearing and embedment depth.

Stainless Steel Collated Nails

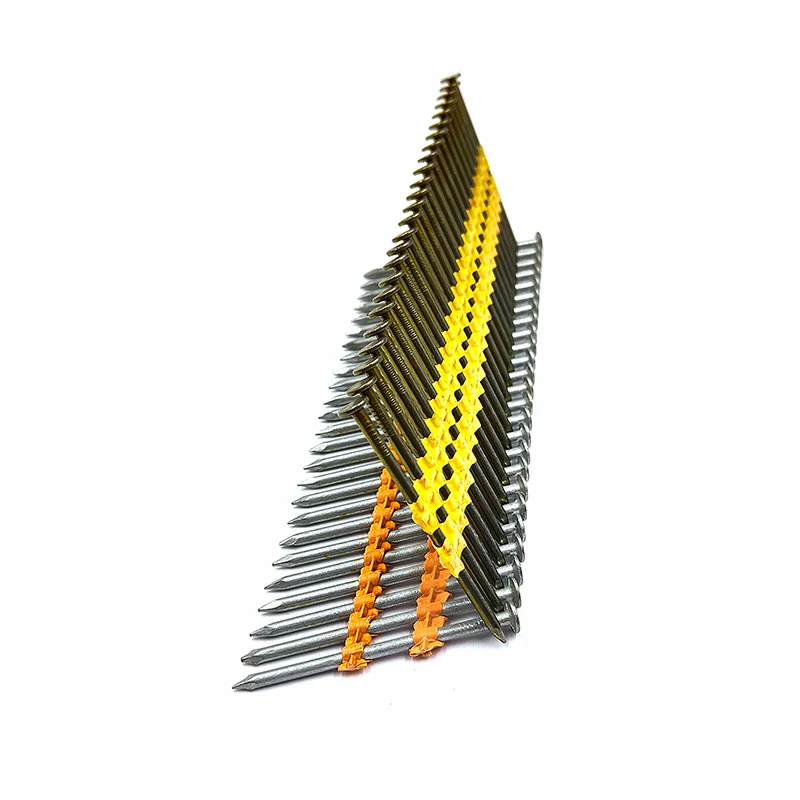

Stainless steel collated nails made from corrosion resistant alloys like 304 prove ideal for outdoor and wet locations. Being completely rust proof, stainless nails maintain holding strength even in the harshest environments. Stainless collated nails typically range from 15 to 90 degrees in finish and 8G to 15G in gauge. They find applications anchoring decking, siding and roofing materials as well as assembling outdoor furniture. 21 degree plastic collated nails 17-4PH and 301 stainless steel varieties offer high hardness and strength at elevated temperatures for thermally demanding applications. However, stainless fasteners cost significantly more than standard carbon steel nails.

21 Degree Galvanized Framing Nails

Framing nails with a 21 degree finish prove particularly rugged for assembling outdoor structures. The extra incline on the nail point relative to standard 15 degree nails aids penetration into tougher wood types with less splitting. Available both in carbon steel and stainless steel, 21 degree framing nails feature nail points 2-3 times hardened for secure fastening into pressure treated lumber and denser hardwoods. While they require deeper embedment, 21 degree framing nails withstand the elements and provide dependable holding in beams, posts and studs. Head styles for 21 degree framing nails include common, box, screw and crown options.

Other Factors to Consider

When using durable concrete, stainless steel or 21 degree galvanized framing nails for your fastening needs, consider:

• Material compatibility: Check if intended materials can endure more abrasive and hardened nail points.

• Embedment depth: Ensure adequate penetration into substrates for maximum performance.

• Recoil resistance: Use an nail gun with optimized settings for reduced kickback with hardened nails.

• Fastening capacity: Match nail size and length to the load bearing requirements of the job.

• Additional corrosion protection: Apply sealants over exposed portions of carbon steel nails for longevity.